|

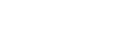

One of the great approaches for cold climate countries to improve the efficiency in buildings where photovoltaic system could not be generate sufficiently, is through CHP (cogeneration of heat and power) plant.

ApplicationsThere is various use of the CHP plant, but most of them are used where there is a large demand in heating such as cold countries where large plants produce the heat that is distributed to buildings just by connecting to the network. Additional to natural gas, the water could be heated from biomass or even landfill waste could be incinerated to be used in another form by people. The CHP could be used for campus, hospital, or industrial complex in order to be independent from the grid. Our team, have work on an industrial project in Mexico desiring to be self-sufficient in electricity even if heating is not required, however they have a 24h manufacturing cooled facility. Thus, the CHP heat is converted into chilled water for conditioning with an absorption chiller and the electricity produced helps reduce their consumption to 45% while lowering the maximum demand load number. Modeling and LEED Our energy modeler experts have documented various LEED projects that take advantage of CHP plant at local or district level. The preferred approach is to model the plant directly as a heating and electricity source, this is more than simple using IESVE. The information required are the efficiency curves, the network distribution loss, and the maximum heat output from the plant. This component is connected directly to the hot water loop, or chilled water loop when using absorption chiller, to provide the required heat at each second while generating energy. We highly recommend to model the CHP instead of manually inputting the contribution to your energy results, to be able to visualize CHP plant operation and how the electricity maximum load evolves. Please share your opinion below, your participation means a lot to us.

* CHP Technology, https://no.pinterest.com/pin/425027283577204903/

0 Comments

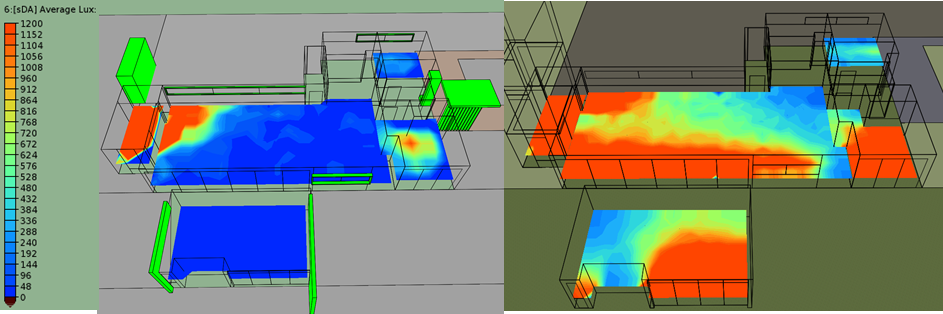

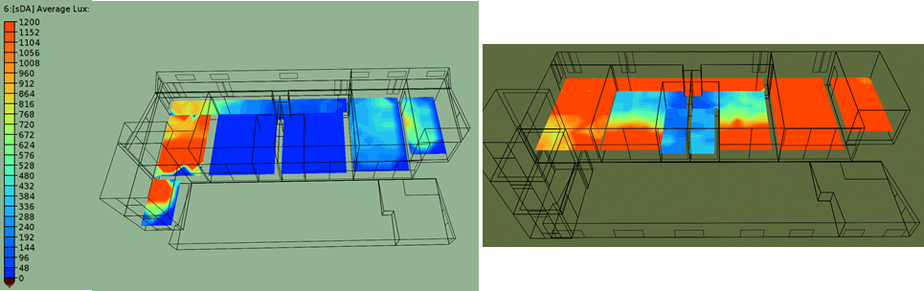

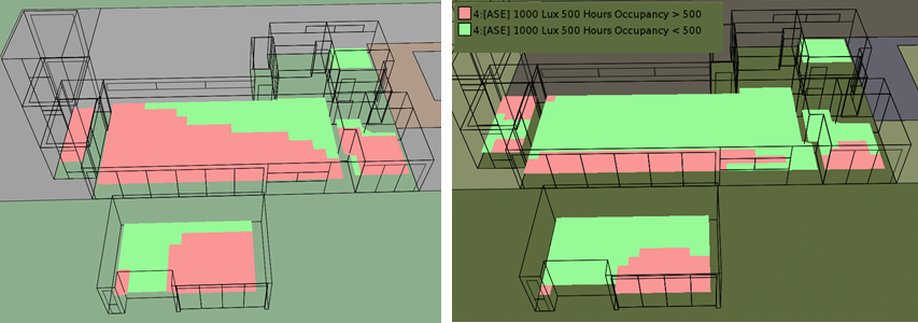

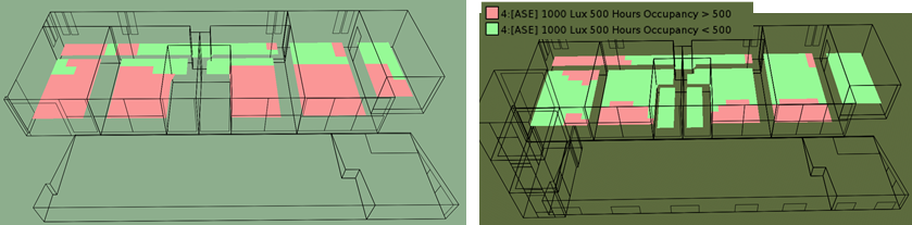

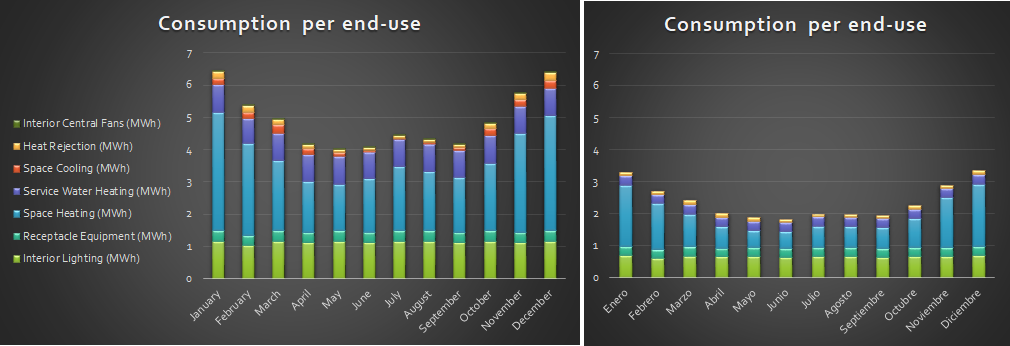

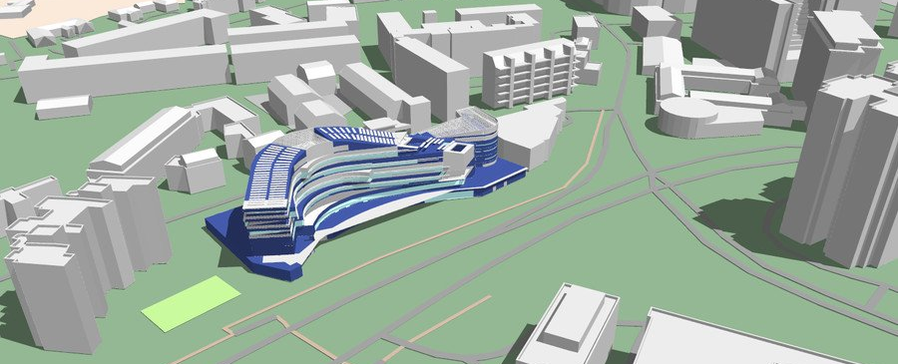

The architecture industry is evolving to be more integrated and focusing on reduced energy consumption and increasing occupant comfort. Our team has worked closely with OWN*, Environment Friendly Mexican Architecture firm, to improve their latest single-family project at conceptual design phase. Our objectives were to reach Net-Zero Energy, maximize daylight while minimizing glare and take advantage of natural ventilation for passive cooling. We perform analysis using a building energy model and CFD simulations. The site climate requires to reduce heating consumption in particular during the night and reduce cooling consumption at mid-day. The temperature is reaching lower temperatures in January, but it is quite constant through the year since the project is located in the north tropical region. We thus would need to reduce slightly solar gain at summer when the sun is at its zenith, this was achieved by adding light shelves that are required to minimize glaring and increase daylight penetration. The light shelves location to not interfere with glass door operation were placed above them, thus additional glazing was placed above the lights shelves. The additional glazing would also contribute, those openable, to increase the natural ventilation potential. However, the light shelves were not enough to reduce the glare enough, thus a glazing film that reduces the visual light transmittance to 17% in strategic locations. These strategies allow the increase in daylight from 34% sDA** to 76% sDA and reduce glare from 72% ASE*** to 25%ASE, all numbers are the weighted average for the occupied spaces. To study the heating/cooling demand and energy consumption we develop a reference building which is based on the IECC-Mexico 2016 and the NOM-020-ENER-2011. Per the client request we use Autoclaved Cellular Concrete blocks with 51mm Polystyrene insulation, double glazing and UPVC window framing. The reduced consumption from these measures was only 17% compared to the IECC reference. Thus, we implement in addition the use of instantaneous water heaters, LED interior and exterior lighting, daylight and presence sensors, EnergyStar home appliances, and outdoor air supply with heat recovery. Combining these approaches we reach savings of 52% in yearly energy consumption compared to the reference building. Finally, the software used permits the evaluation of photovoltaic system generation. This guided the change of the first floor roof angle center location to increase the south-oriented area in order to accommodate more solar panels. The change allows the number of solar panels to be double which was required to reach the net-zero threshold we were looking for. The roof change also opens a larger area in the north facade which benefits the natural ventilation performance. This would be discussed in a future article. Please share your opinion below, your participation means a lot to us.

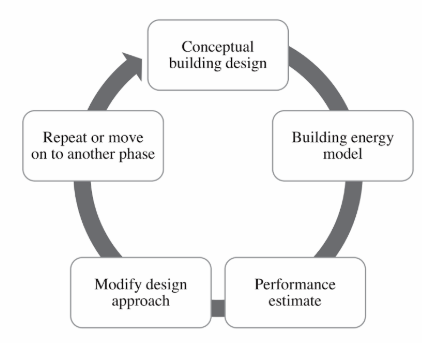

* OWN, Architectural Firm with focus on balance between human and nature, www.thisisown.com/. ** sDA: Spatial Daylight Autonomy, measure defined in standard IES LM-83-2012. *** ASE: Annual Sunlight Exposure, measure defined in standard IES LM-83-2012. On April 24, 2018, has been published the long-awaited ASHRAE Standard 209-2018, Energy Simulation Aided Design for Buildings except Low Rise Residential Buildings, which describes the most beneficial use of energy modeling for any constructions. I believe that it is a great reference for energy modeler however, it is not tomorrow that all projects will comply to this standard of using energy model to inform and optimize the design through 11 cycles from early concept to post-occupancy.

Please share your opinion below, your participation is our motivation to write every week. Recommended additional content:

|

Suggest topicsWeekly our team select the most relevant topic of the industry to talk about. However, our readers' interests are even better. Archives

June 2021

Categories

All

|

GREEN BUILDING CERTIFICATION - ENERGY MODELING - |

Offices | OficinasCalle 20 438, Oficina 116,

Colonia México, Mérida, Yucatán, México 97125 +52 999 838-0096 [email protected] |

Copyright © 2018-2024 Chaac Simulaciones Inc. All Rights Reserved.

|

RSS Feed

RSS Feed